- Ursprungsort:

-

Guangdong, Porslin (Fastland)

- Varumärke:

- Modellnummer:

-

MK30926A02B

- Basmaterial:

-

FR-4

- Koppartjocklek:

-

1uns

- Brädets tjocklek:

-

1.6mm

- mig. Hålstorlek:

-

4tusen

- mig. Linjebredd:

-

4tusen

- mig. Linjeavstånd:

-

4tusen

- Ytbehandling:

-

ASSL/ENIG/OSP

- Lödmask:

-

Grön,Röd,Svart,Gul,Blå,Orange,Purpur

- Standard:

-

IPC-A-610D

- Laserborrhålstorlek:

-

0.1mm

- Kopparviktstolerans:

-

± 0,25 oz

- Brädtjocklekstolerans:

-

±10 %

- Maximal dimension:

-

610mm*1100mm

- V-poäng djup:

-

20%~25% av skivans tjocklek

- 100% Funktionstestning:

-

Ja

- Blyfri teknik:

-

Ja

- Certifikat:

-

RoHS,UL,EG,ISO9001, ISO14001

- Försörjningsförmåga:

- 10000 Kvadratmeter/kvadratmeter per månad

- Förpackningsuppgifter

- Innerpackning :Vakuumpaket

Yttre packning: Standard kartonglåda

- Hamn

- Shenzhen

- lead Time:

- 3-5 dagar

Kylskåpstemperaturkontroll PCB-modul med blyfri teknik

1. Oem & ODM elektronisk PCB/PCBA design och ingenjörskonst.

2. HASL/ENIG/OSP ytbehandlingsteknik.

3. DIP/SMT/SMD komponentmontering.

4. AOI, ICT, Metoder för funktionstestning.

5. UL,RoHS, SGS, ISO9001, ISO14001 godkänd.

6. 2-års garanti, vi skyddar dina lagliga intressen även om vi befinner oss i olika länder.

Vi gör speciell specifikation PCB/PCBA som du vill, skicka oss Gerber-filen och BOM-listan för en offert. (Dina konfidentiella dokument&Immateriella egenskaper är under vårt skydd!)

Ditt förtroende gör det till en stor ära för vårt team att tjäna för ditt intresse! Vi tar din åsikt på allvar.

En styckebeställning accepteras. Kontakta oss FÖR MER INFORMATION(Klicka för att besöka vår förstasida)

Företagsprofil

Grundades under året 2001, ligger i Shenzhen, som en professionell OEM/ODM-tillverkare, MOKO är född för att producera högkvalitativa produkter, ge den bästa ingenjörstjänsten, servera för våra kunder’ kärnintressen. Vi kunde ge en-stop nyckelfärdig PCB-montage service,

vi erbjuder också:

– Kontraktstillverkning

– Ingenjörstjänster

– PCB design & hopsättning

– Komponentupphandling & Materialhantering

– Produktdesign

– Fast Track Prototyping

– Kabel- och trådaggregat

– Plast och formar

– Funktionstesttjänst

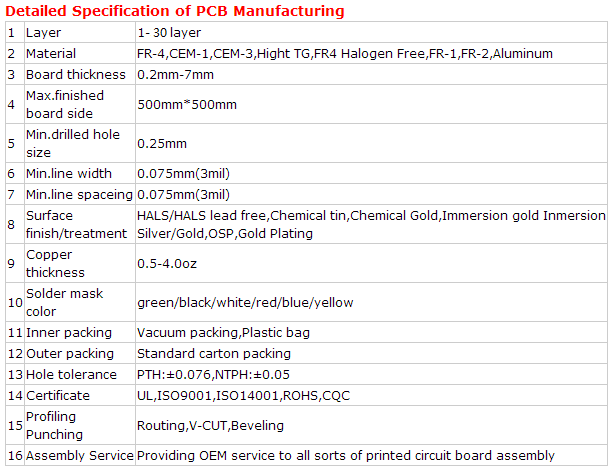

Tekniska krav:

1) Professionell ytmontering och genomhålslödningsteknik

2) Olika storlekar som 1206,0805,0603 komponenter SMT-teknik

3) ICT(In-Circuit Test), FCT(Funktionell kretstest) teknologi.

4) PCB Montering Med UL,EG,FCC,Rohs godkännande

5) Kvävgasåterflödeslödningsteknik för SMT.

6) Hög standard SMT&Löd monteringslinje

7) Hög densitet sammankopplade kortplaceringsteknikkapacitet.

Offertkrav:

· Gerber-fil på det nakna PCB-kortet

· BOM (Materialförteckning) för montering

· Förkorta ledtiden, vänligen meddela oss om det finns något godtagbart utbyte av komponenter.

· Testguide & Testa fixturer vid behov

· Programmering av filer & Programmeringsverktyg vid behov

· Schematisk vid behov

Avancerad PCB-monteringsutrustning:

· SMT-maskin: SIEMENS SIPLACE D1/D2 / SIEMENS SIPLACE S20/F4

· Återflödesugn: FolunGwin IN RX860

· Våglödningsmaskin: FolunGwin ADS300

· Automatiserad optisk inspektion (AOI): Aleader ALD-H-350B

· Helautomatisk SMT-stencilskrivare: FolunGwin Win-5

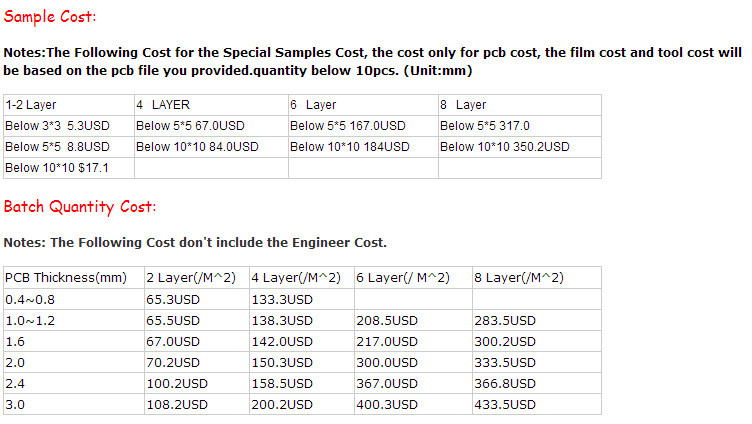

Kosta & Ledtid

PCB ledtid:

PCB ledtid:

| Enkel / dubbel sida | 4 lager | 6 lager | Ovan 8 lager | HDI | |

| Prov ledtid(Vanligt) | 5-6 | 6-7 | 7-8 | 10-12 | 15-20 |

| Prov ledtid(Snabbast) | 48-72 timmar | 5 | 6 | 6-7 | 12 |

| Massproduktion ledtid(Första omgången) | 7-9 | 10-12 | 13-15 | 16 | 20 |

Förpackning & Frakt

Leveransmetoder

1.Av DHL, UPS, FedEx, TNT använder kundkonto.

2. Av EMS (Vanligtvis för ryska kunder), men priset är högt.

3. Till sjöss för masskvantitet enligt kundens krav.

4.Av kundens speditör

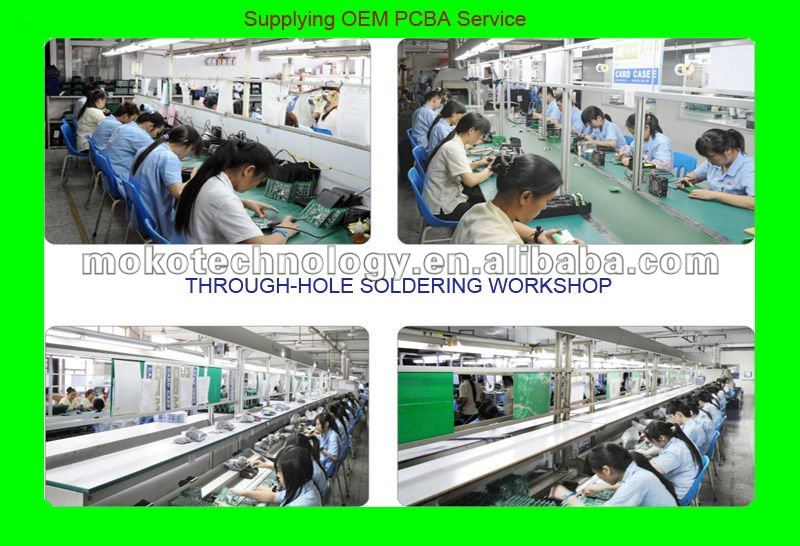

Utsikt över MOKO Factory

1)RoHS SMT-bearbetning:

2)Högstandard lödningsverkstad för genomgående hålkomponenter

3) Fullt utrustat funktionstestrum för kretsar

PCBA Products Showcase

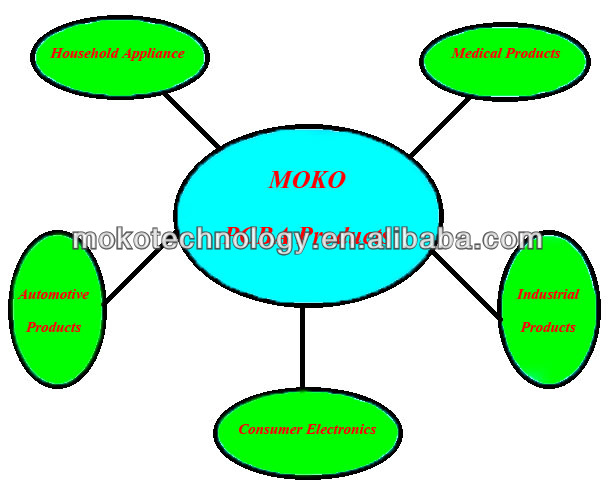

Produktapplikation

Vanliga frågor

F:Vilka filer använder du i tillverkningen av bara board?

A:Gerber RS-274X,274D,Eagle och AutoCADs DXF,DWG

F: Vilka filer behöver du i PCBA-projekten?

A: Förutom PCB-filen, PNP(Välj och placera) fil och Components Position-fil behövs också.

F: Hur kan jag känna till behandlingen av min PCB- eller PCBA-beställning?

A: Varje kund har en försäljningschef som kontaktar dig. MOKO arbetstider:AM9:00-PM6:00(Peking tid) från måndag till fredag. Vi kommer att svara på din e-post 2 timmar i vår arbetstid. Och du kan också kontakta vår försäljning’ mobiltelefon om det är brådskande.

F: Kommer vår produkt att testas före leverans?

A: Ja, vi kan tillhandahålla funktionskretstestning om du ger oss testmetoderna.

https://www.alibaba.com/product-detail/Frigerator-temperature-control-PCB-module-with_60312447065.html?spm=a2700.7724838.2017115.11.35cf5a5fWQnpW7