- Place of Origin:

-

Guangdong, China (Mainland)

- Brand Name:

- Model Number:

-

MK30926A02B

- Base Material:

-

FR-4

- Copper Thickness:

-

1oz

- Board Thickness:

-

1.6mm

- Min. Hole Size:

-

4mil

- Min. Line Width:

-

4mil

- Min. Line Spacing:

-

4mil

- Surface Finishing:

-

HASL/ENIG/OSP

- Solder Mask:

-

Green,Red,Black,Yellow,Blue,Orange,Purple

- Standard:

-

IPC-A-610D

- Laser Drill Hole Size:

-

0.1mm

- Copper Weight Tolerance:

-

± 0.25oz

- Board Thickness Tolerance:

-

±10%

- Maximum Dimension:

-

610mm*1100mm

- V-score depth:

-

20%~25% of board thickness

- 100% Function Testing:

-

Yes

- Lead Free Technology:

-

Yes

- Certificate:

-

RoHS,UL,CE,ISO9001,ISO14001

- Supply Ability:

- 10000 Square Meter/Square Meters per Month

- Packaging Details

- Inner packing :Vacuum Package

Outer packing: Standard Carton Box

- Port

- Shenzhen

- Lead Time:

- 3-5 days

Refrigerator temperature control PCB module with lead-free technology

1. OEM & ODM electronic PCB/PCBA design and engineering.

2. HASL/ENIG/OSP surface finishing technology.

3. DIP/SMT/SMD component assembling.

4. AOI, ICT, Function Testing methods.

5. UL,RoHS, SGS, ISO9001, ISO14001 approved.

6. 2-years warranty, we protect your legal interest even we are in different countries.

We make particular specification PCB/PCBA as you want, please send us the Gerber file and BOM list for a quotation. (Your confidential Documentations&Intellectual Properties are under our protection!)

Your Trust Makes It A Great Honor For Our Team To Serve For Your Interest! We Take Your Opinion Seriously.

One Piece Order Accepted. Contact Us FOR MORE INFORMATION(Click to Visit Our Frontpage)

Company Profile

Founded in the year 2001, located in Shenzhen, as a professional OEM/ODM Manufacturer, MOKO is born to produce high-quality product, provide the best engineer service, serve for our customers’ core interests. We could provide one-stop turnkey PCB assembly service,

we also offer:

– Contract Manufacturing

– Engineering Services

– PCB Design & Assembly

– Component Procurement & Material Management

– Product Design

– Fast Track Prototyping

– Cable and Wire Assemblies

– Plastics and Molds

– Function Testing Service

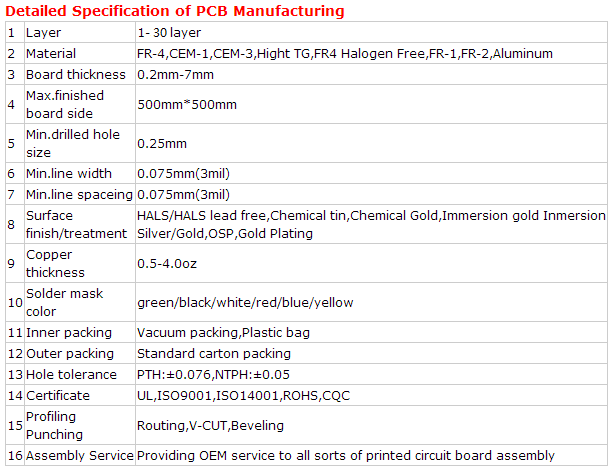

Technical requirement:

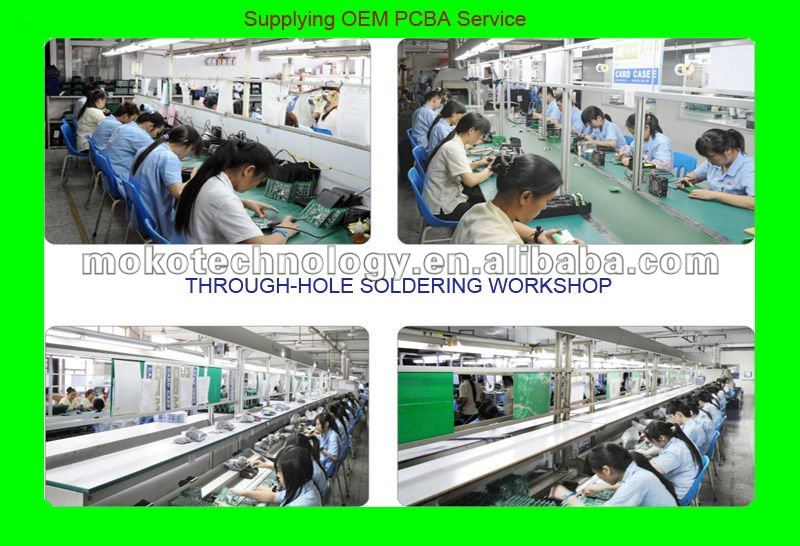

1) Professional Surface-mounting and Through-hole soldering Technology

2) Various sizes like 1206,0805,0603 components SMT technology

3) ICT(In-Circuit Test), FCT(Functional Circuit Test) technology.

4) PCB Assembly With UL,CE,FCC,Rohs Approval

5) Nitrogen gas reflow soldering technology for SMT.

6) High Standard SMT&Solder Assembly Line

7) High density interconnected board placement technology capacity.

Quote requirement:

· Gerber file of the bare PCB board

· BOM (Bill of material) for assembly

· To short the lead time, please kindly advise us if there is any acceptable components substitution.

· Testing Guide & Test Fixtures if necessary

· Programming files & Programming tool if necessary

· Schematic if necessary

Advanced PCB assembly Equipment:

· SMT Machine: SIEMENS SIPLACE D1/D2 / SIEMENS SIPLACE S20/F4

· Reflow Oven: FolunGwin FL-RX860

· Wave Soldering Machine: FolunGwin ADS300

· Automated Optical Inspection (AOI): Aleader ALD-H-350B

· Fully-Automatic SMT Stencil Printer: FolunGwin Win-5

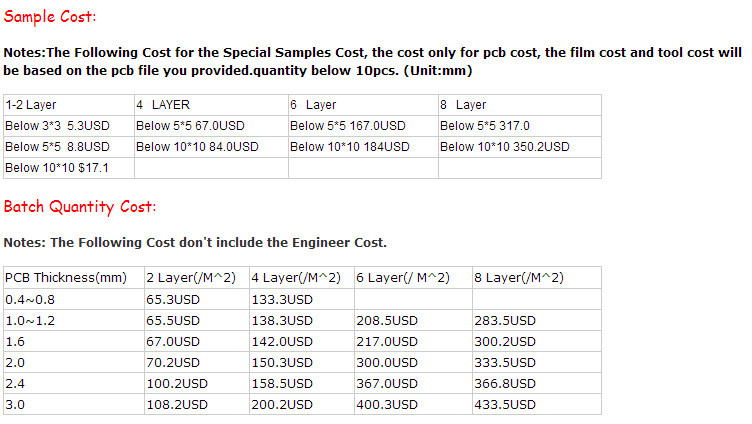

Cost & LeadTime

PCB Leadtime:

PCB Leadtime:

| Single/double side | 4 layer | 6 layer | Above 8 layer | HDI | |

| Sample lead time(Normal) | 5-6 | 6-7 | 7-8 | 10-12 | 15-20 |

| Sample lead time(Fastest) | 48-72 hours | 5 | 6 | 6-7 | 12 |

| Mass production lead time(First batch) | 7-9 | 10-12 | 13-15 | 16 | 20 |

Packaging & Shipping

Shipping Methods

1.By DHL, UPS, FedEx, TNT using clients account.

2. By EMS (Usually for Russia Clients), but the price is high.

3. By sea for mass quantity according to customer’s requirement.

4.By customer’s Forwarder

View of MOKO Factory

1)RoHS SMT Processing:

2)High Standard Through-Hole Components Soldering Workshop

3) Full Equipped Function Circuit Testing Room

PCBA Products Showcase

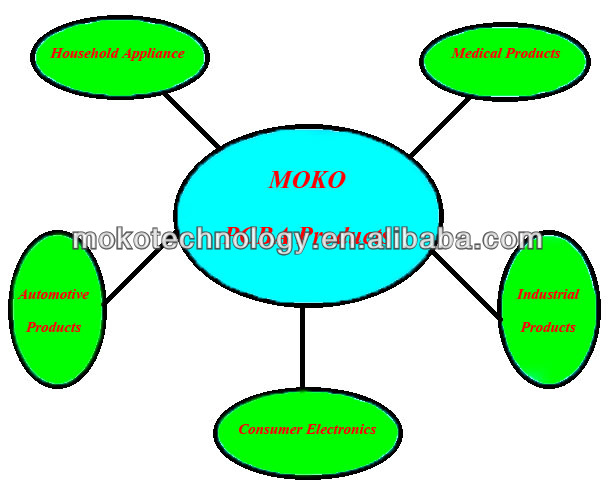

Products Application

FAQs

Q:What’s files do you use in the bare board fabrication?

A:Gerber RS-274X,274D,Eagle and AutoCAD’s DXF,DWG

Q: What files do you need in the PCBA projects?

A: Besides the PCB file, the PNP(Pick and Place) file and Components Position file are also needed.

Q: How can I know the processing about my PCB or PCBA order?

A: Each Customer has a sale manager to contact you. MOKO working hours:AM9:00-PM6:00(Beijing Time) from Monday to Friday. We will reply your email in 2 hours in our working time. And you also can contact with our sales’ cell phone if urgent.

Q: Will our product be tested before shipment?

A: Yes, we could provide Function Circuit Testing if you provide us the testing methods.

https://www.alibaba.com/product-detail/Rifrigerator-temperature-control-PCB-module-with_60312447065.html?spm=a2700.7724838.2017115.11.35cf5a5fWQnpW7